CELCIUS ENERGY, CONTROL, AND SECURITY

Celcius offer a complete energy & security solution to the retail sector focusing on the issues regarding energy saving within the industry.

South Africa has a major problem providing the required energy for the ever growing demand which, as historically proven, leads to increased price. Over and above the energy issues, there are security, control and staffing issues, all of which Celcius offers applicable solutions.

- Energy Saving Retail Dashboard System,

- Night Blinds,

- Heat Reclamation,

- Solar Heating.

Energy Saving Retail Dashboard System

So what would you see on the dashboard:

-

Energy Management: Energy Usage and monitoring dashboard with set targets.

-

Entire Store Control: Full control system for a store – ovens, lighting, certain aspects of refrigeration, geysers, hot and cold equipment and many other 3rd party applications.

-

CCTV.

-

Time & Attendance.

-

Access Control; below you will see the various Options that are available to retailers.

-

Remote Reports and Management

Energy Management:

Audits:

Celcius offer a full range of energy audits and provide reports once completed – taking it a step further we provide solutions for all the problem areas, that give you full control and management.

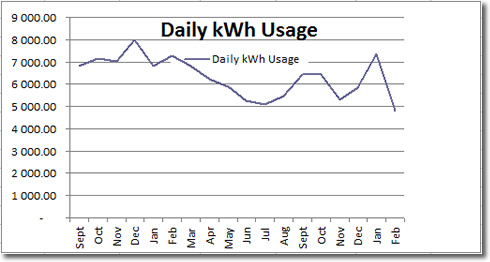

Energy Data Loggers:

Energy data loggers measure and record performance levels in a variety of applications. There is a saying: if you don’t have data you don’t have control, never mind management. With data loggers that we integrate into our software, retailers are able to see a full complement of figures and reports, including:

- Power Factors

- Maximum Demands

- KVA

- KWH

- Peak Periods

Power Factor Correction:

What Does Power factor really mean?

We've all heard of the term 'Power Factor Correction'. That phrase is probably too deeply embedded in electrical terminology to be deleted from our thinking. Unfortunately, it is misleading. Correction implies the existence of some specific circuit defect, which can be made right by adding some specific "corrective" measure. Power Factor, however, doesn't work that way. It is a continuously variable phase relationship between current and voltage. We can raise it or lower it, but no correct / default level automatically results from a single adjustment.

Reactive power charges can be made significantly smaller by the introduction of Power Factor Correction Capacitors, which is a widely recognised method of reducing an electrical load and minimising wasted energy, improving the efficiency of a plant and reducing the electricity bill.

The simplest way to explain it: Power factor is the phase difference between the sine wave of the voltage and current. In a perfectly resistive circuit, if you observe the voltage and current waveforms on an oscilloscope you see that they both track at exactly the same time; as the voltage rises, the current rises at the same time. In an inductive circuit (such as an electric motor drive) the voltage waveform leads the current waveform by a certain amount of time. This difference in phase is what is refered to as the Power Factor.

Wireless Control Systems with redundancy:

Having being involved in retail for many years, Celcius have developed a wireless control system that adds simplicity and caters for all the variables that occur in the retail environment effortlessly.

Gone are the days when BUS wired systems, SCADA and expensive controllers and PLCS are used. Simple, flexible and reliable are our theory behind any system that is designed.

All the controllers have full audit capabilities, and log files to ensure redundancy and accountability without taking away the functionality and simplicity.

Our current retail stores do not have switches and controls, but rather a simple schedule running through our powerful software that enables the manager to get on with his business as his stores start up on their own managing times and loads.

Our wireless-control-system controls:

- The store, office, back-up and outside lights

- Signage lighting

- Ovens, provers and any other warmers including fryers, warmers and grillers

- Extraction fans

- Geysers

- Refrigeration solenoids and fans

- Most HVAC units – central or split

- Refrigeration Cabinet lights and anti sweats

- Drop temp areas

All the hardware comes with override safeties that, when overridden, fall back to normality. These phases are monitored and reported, indicating which user has overridden the system.

Powerful Software – Dashboard – information at a glance:

Our software has been developed specifically for the retail industry and aims to give managers and owners ease of use, and remote control anywhere in the room.

The software has to be functional without loosing functionality – yes it sounds strange but we have got it right. The software communicates through our self-developed modem to the wireless network of devices sending and checking commands continuosly.

-

Scheduling – the software will be programmed through drag-and-drop icons in order to automate the running of the store. With the understanding that retail stores never operate in the same way everyday, we have embedded the capability to switch units from a central PC (every schedule is recorded and logged).

-

Overides – there are overrides that can be triggered from the software. These require a password and create full audit trails.

-

Logging – each trigger has a time-log on it, so we are able to determine running times.

-

National Power outage alerts.

-

Remote dial in – we have the facility to do maintenance over the WAN. It is an efficient way to deal with changes, maintenance and repairs. Our retailers have full access through their laptops and PDA’S.

-

Alerts and controls are available through an interface via twitter.

-

Temperature-monitoring and Graphs including sms and email alerts (see Wireless Temperature Sensing).

Reporting:

Once the system is installed we provide a monthly report fee-structure, and various model reports are available:

- Energy usage TOU

- Maximum demand

- Override report

- Corrective solution report

- Year-on-Year Comparison

- Target-monitoring (regarding usage)

- Coldroom door opening time

- Temperature defaults in refrigeration cabinets

We at Celcius recognise the importance of making use of the data we collect, and ensure that we always provide the solution that was initially specified. This is managed and controlled through automated reporting that provides the owner and manager the data at their finger-tips, rather than making assumptions.

Wireless Temperature Sensing:

Celcius equip the refrigeration cabinets, back up areas, plantroom and cold/freezer rooms with a wireless temperature sensor that collects temperature.

This system is developed for assisting in HACCP. It also assists as a 3rd party temperature information provider and can not be manipulated by your refrigeration contractor to cover mistakes.

Built into the software:

- 15-30min temperature sensing

- Graphical representation for easy fault finding and clarity

- Alerts through sms and e-mail to management and the contractor

Coldroom Door Monitoring:

Need we ask how many hours a day are your cold room doors open – do you know or even better do you want to know – YES

Our sensors can send data to the server to calculate exactly how long the staff are opening the doors. YOU may be amazed. This definately has an impact on efficiency of refrigeration plants.

Access Control and Time & Attendance:

- Biometric & Tag Systems.

- Physical Barriers, turnstiles, booms and spikes.

- Full Zone control.

- Export into VIP.

- FULL Time & Attendance.

Surveillance:

- Analogue or IP Solutions.

- POS integration.

- Off Site monitoring through 3rd party.

- Fully integratable into mini BMS.

- Remote and PDA monitoring.

- Alerts and e-mails.

Intrusion:

- Full Intrusion alarm systems.

- Indoor and Outdoor.

- SMS alerts and e-mails.

- Remote access.

- Wired and Wireless Systems.

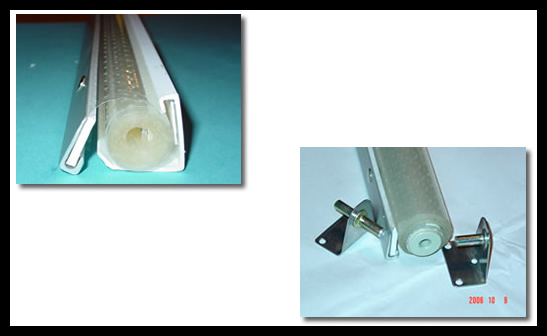

Heat Reclamation

Rather than expel waste heat from the refrigeration plant to the atmosphere via a cooling tower, the heat is transferred to a warm glycol/water solution. The glycol solution is pumped throughout the building to heating equipment such as radiant floor piping in snow melting pits and seating areas, air handling coils serving occupied spaces and domestic water pre-heat coils.

• Recovers waste heat that is typically rejected to the atmosphere through the cooling tower.

• Reduces natural gas use.

• Reduces greenhouse gas emissions.

• Realistic payback period of 4-5 years.

Solar heating

Although not always ideal in the supermarket environment due to positioning and long runs within some Supermarkets, sometimes it becomes a viable opposition to use solar panel for geysers and boilers, and perhaps some back up lighting.

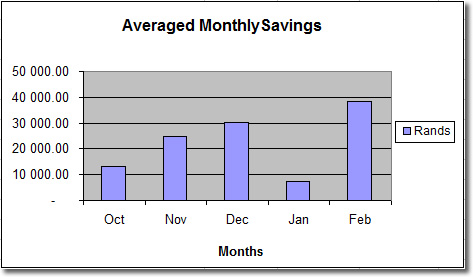

Energy Saving Statistics